To Be or Not to Be (Flexible)

Okay, folks. It may be time for me to actually write about something specific pertaining to our PULSEROLLER products. I have opined and waxed rhapsodic in the last few articles so much that I may have strayed from the original intent of this column, which is to provide tips, tricks, explanations, and other such unabashed ballyhoo for our PULSEROLLER products. So, without further ado, and much to the delight of my editor and marketing director, I will return to talking about a ConveyLinx function or feature.

Flex Zone

The ConveyLinx feature du-jour for today’s task is Flex Zone recognition and cases when you want it (To Be) and when you don’t’ want it (Not to Be).

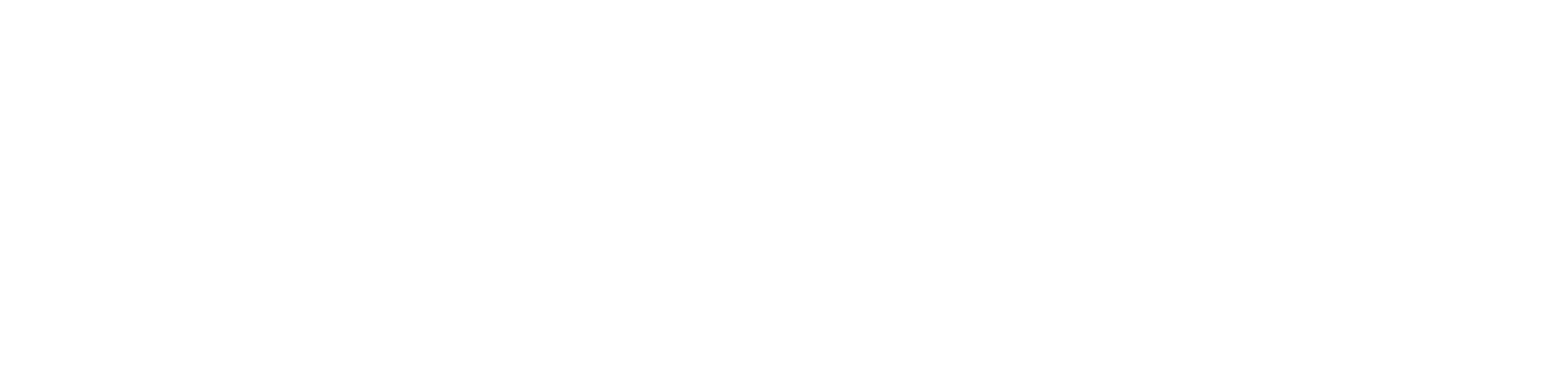

Flex Zone is enabled by default when you Auto-Configure a network of ConveyLinx modules. If these modules happen to be unlocked and/or brand new out of the box, they will configure with ZPA functionality and default to Singulation Release mode. Here’s what happens when ConveyLinx is in ZPA Singulation Release mode with Flex Zone enabled: When a carton shows up at a zone’s sensor, this zone takes a peek at the status of the upstream zone from which the carton just left. If this zone indicates that its sensor is also blocked, the zone the carton just arrived on turns on Flex Zone. The following picture shows what happens when Flex Zone is enabled and cartons release from their zones:

Flex Zone keeps cartons from jamming when you have some cartons that are longer than one zone.

The Rub

OK. Here is the rub. There may be circumstances when you do not want this behavior. I can think of a couple:

Higher Speed Applications

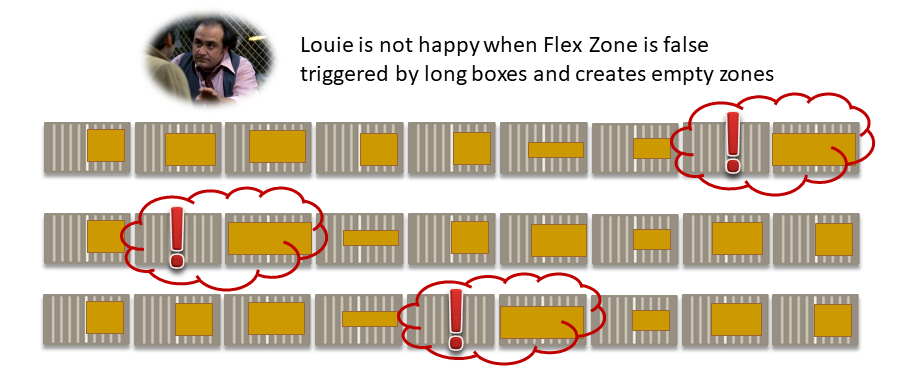

Let’s say we have 30” zones (30” between sensors) and a relatively high percentage of cartons we are handling are close to 30” in length (say 27” or 28” for example). Even though these example cartons are technically shorter than a zone length, at high enough conveyor speeds, they can wreak havoc on the Flex Zone detection. Here is how: There is a finite amount of time required for modules to communicate over a network. In this case, if the speed is fast enough; when Carton A reaches sensor A, the upstream module will not have had time to update its status to indicate that Sensor B is clear. So, Sensor A’s zone believes that Sensor B is still blocked. Thus, it raises its little zone hand and yells “I am in Flex Zone, hear me roar!” If this is happening when your conveyor is mostly running and not accumulating, you will probably see what looks like sporadic and odd behavior with cartons delaying their release in some zones for no apparent reason.

If this happens on long lines of conveyors that accumulate often; you will see some empty zones with cartons in the zones upstream of these empty zones. It will appear that there is something wrong: why aren’t these empty zones getting filled? To illustrate in real-world terms why this could be a problem; picture Louie from the TV show Taxi (I know this makes me old). Louie was played by Danny DeVito (you youngsters look him up on Google). He’s the boss. Short. Stocky. Disheveled hair. Loose tie. Shirt-sleeves rolled up. Always in a foul mood. He’s our warehouse manager and his paycheck is determined by how many boxes he pushes through his warehouse. He walks out from his boss perch and sees accumulated conveyors with empty zones. This does not make Louie happy. You do not want to make Louie any more unhappy than he already is. He expects all available space on his conveyors to be filled with cartons. Empty zones equal smaller paychecks.

We need to disable Flex Zone so that all zones get occupied. All zones occupied makes Louie less unhappy.

Simple Transportation Conveyor

You can set up your ZPA conveyor to operate in a “quasi” transportation way by manipulating some settings in EasyRoll, one of which is disabling Flex Zone. This was covered in detail in a previous Pat’s Corner article titled Simple Transportation Conveyor so I won’t reiterate this here.

How to Disable Flex Zone

First of all, you cannot enable or disable Flex Zone for a single zone or module. You must do this for the entire subnet of a network. Keep this in mind if you have an application for a larger system where you want some of it to have Flex Zone enabled and other parts to have Flex Zone disabled.

Simply go to the Flex Zone tab in the Advanced Dialog of EasyRoll and click either the Enable All or Disable All button. It will take a few seconds because each module in the subnet has to make the change to itself. Then you are done.

Errata

Here comes the disclaimer portion of this article. Flex Zone does not operate in zones that are set to Train Release mode. In truth, Flex Zone detection doesn’t get intentionally disabled when you are in Train Release mode, per se; it just doesn’t work. There very well may be a “perfect storm” of circumstances out there where a specific mixture of zone length, carton length, and conveyor speed are combined with having Flex Zone enabled and Train Release mode active simultaneously that will result in some noticeable weirdness. Our support staff has yet to encounter any callers with any such symptoms or weirdness. The takeaway here is that you probably do not need to disable Flex Zone for a subnet where you are using Train Release, but it may be a good thing to try if you are seeing some unexplainable weirdness.

In one of my embarrassing documentation oopsies, older versions of our ConveyLinx User’s Guide could have maybe, kinda, sorta, coulda, in an off-hand way been remotely inferred and/or interpreted as indicating that Flex Zone worked in Train Release mode. OK. It definitively said in 12-point Calibri font that Flex Zone would work with Train Release mode. This was patently incorrect. Please download our latest ConveyLinx ERSC User’s Guide so you always have (what we believe) is the most error-free and accurate information.

As the great bard Shakespeare wrote for Hamlet at the beginning of his famous soliloquy: “To be or not to be, that is the question….” Well, if the question is whether to be flexible or not with your ZPA conveyor, hopefully now you have an answer.